Advantage/Notice

- All material contacting parts of stainless steel

- Big material passages

- Easy maintenance and repair

- Fixed mixing ratio 1 : 1 - continuously electronically monitored

- You can find more information on the application and process techniques with the DESOI w.i.l.m.a. in the STUVA ABI leaflet "Sealing of structures by injection", 4th edition - Part III/1.3.2 from p. 57.

Material to be used

- acrylate gel

Technical data

| Working pressure - infinitely variable | 5 - 120 bar |

| Delivery rate | |

| - with air performance of 0,7 m³/min (2 x compressor V-Meko 400) | max. 10 l/min |

| - with air performance of 1.3 m³/min | max. 13 l/min |

| Air consumption | min. 0.5 m³/min |

| Transmission ratio | 1:15 |

| Mixing ratio | 1:1 |

| Air pressure | max. 8 bar |

| Weight | 85 kg |

| L x W x H | 77 x 55 x 112 cm |

| Rinsing pump | |

| Working pressure - infinitely variable | 7 - 220 bar |

| Delivery rate | 5 l/min |

| Transmission ratio | 1:27,5 |

| Control cabinet | |

| Supply voltage (adjustable ex works) | 110 - 230 V/0,5 Ampere |

| Storage type | digitally on tablet |

| Data transfer | WLAN |

| Measuring range - volume (depending on the sensor) | 100 l/min. |

| Measuring range - pressure (depending on the sensor) | max. 250 bar* |

| Measurement accuracy | ± 2 % v ME |

| Weight | 8.62 kg |

| L x W x H | 30 x 19 x 33 cm |

| *1 bar = 105 Pa. (Pascal) | |

| Tablet | |

| Storage type | digitally on tablet |

| Hard disk space | 64 GB |

| Data transfer | WLAN |

| Weight - tablet | 1,26 kg |

| L x W x H - tablet | 28 x 19 x 3,5 cm |

Product description

The combination DESOI w.i.l.m.a. and DESOI AirPower M35-3C VA is ideal for injection work with acrylic gel. The piston pump achieves a delivery rate of max. 13 l/min at a mixing ratio of 1:1 and is equipped with a separate rinsing pump. The sealing sets inside are protected by an integrated spring pre-tensioned, manual re-tensioning is not necessary. DESOI w.i.l.m.a. monitors and documents the material consumption, the injection pressure and the mixing ratio.

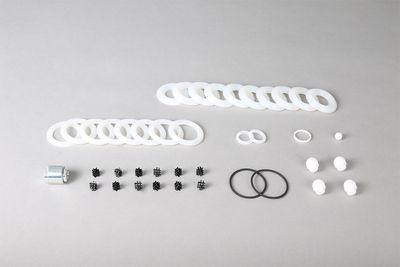

Accessories