Inflatable packer

More InformationsFilter

2 Show Variants

9 Show Variants

2 Show Variants

2 Show Variants

2 Show Variants

4 Show Variants

2 Show Variants

10 Show Variants

3 Show Variants

4 Show Variants

3 Show Variants

2 Show Variants

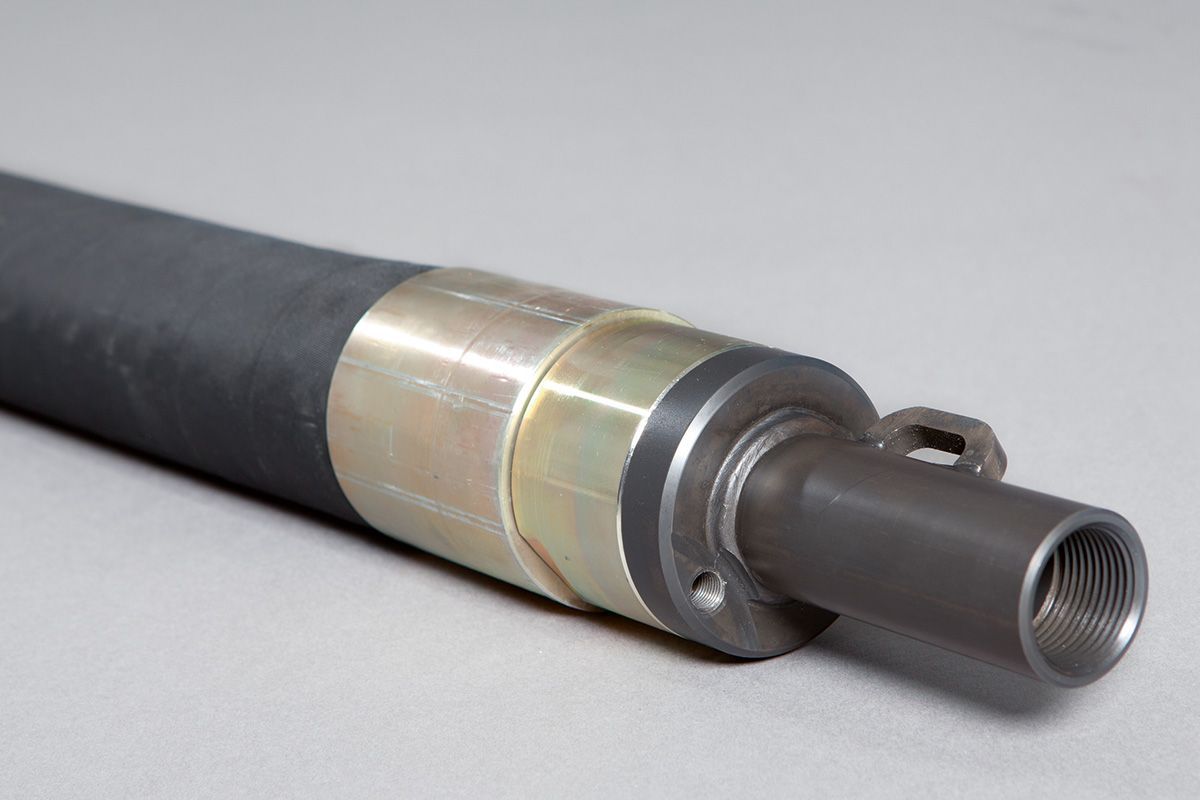

INFLATABLE PACKER

Inflatable packers are used for injections in nearly all areas of the boring technology, tunneling, and special civil engineering. These injections generally serve for the improvement of mechanical properties or for sealing purposes. Moreover in the field of borehole measurement technique inflatable packers are used for test injections, water pressure tests, and for geological reconnaissance boreholes.

Inflatable packers

Examples of application

- Consolidation of ground in different depths

- Consolidation of unconsolidated material

- Consolidation of fissured solid rock

- Injections in building components

- Injections into the soil below building components

- Sealing works

- Lifting injection

Advantages

- Reusable

- Material-conducting parts of stainless steel or with hardened sealing surface

- Easy and safe sealing of boreholes

- Can be used in different depths

- All parts are easily exchangeable

Installation

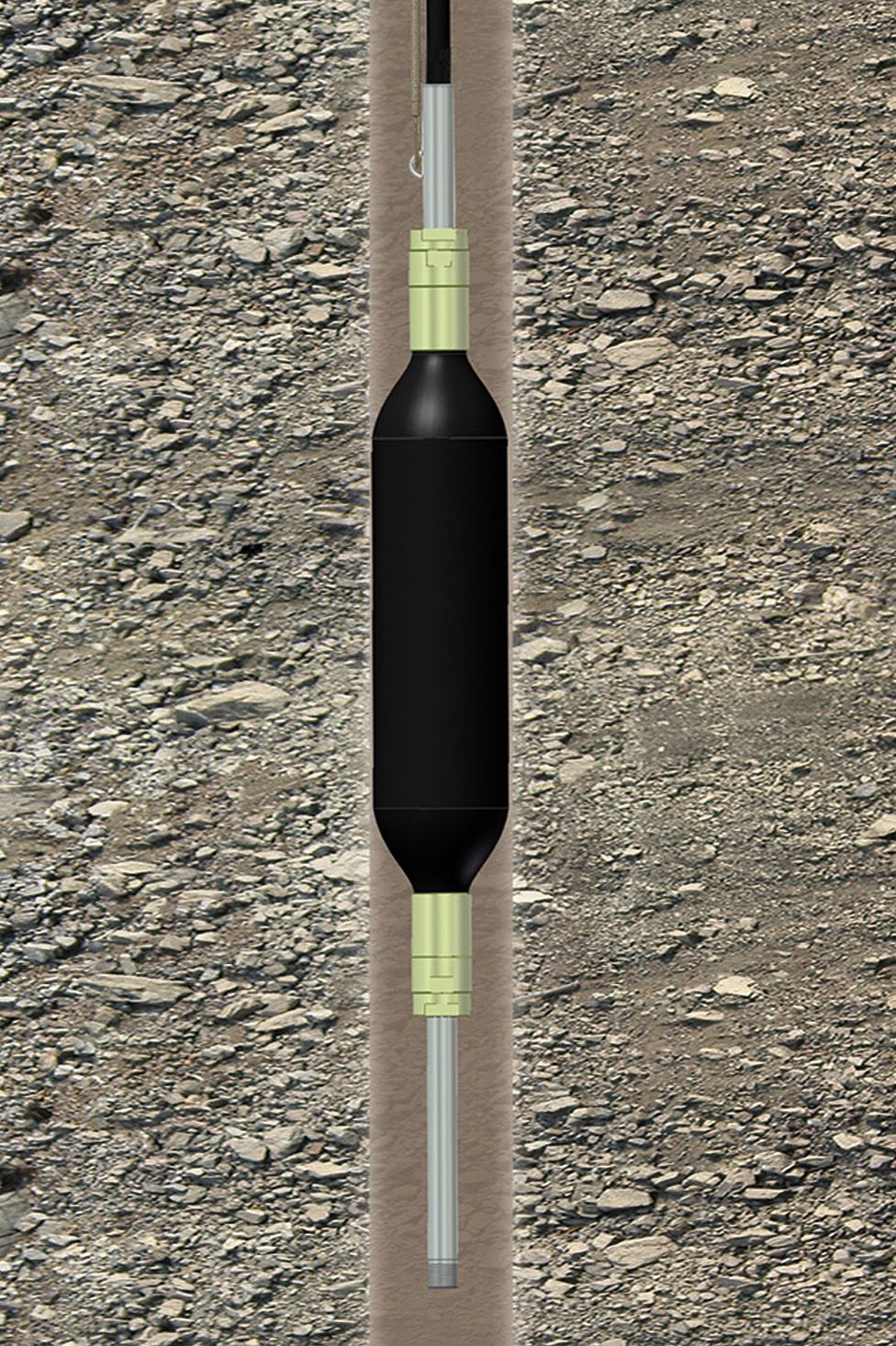

Depending on the type of packer a securing cord or the material hose is used to place the packer in the borehole. The inflatable packer is lowered in the borehole either by the securing cord or the material hose. After the injection the packer can be safely removed and reused. If the borehole is not vertical the inflatable packer must be placed with linkage.Expansion range of the inflation hose

The advantage of inflatable packers is the large expansion range of the inflation hose. According to the type of packer the expansion ranges to the double of the minimum borehole diameter. Moreover the inflatable packer generates a perfect sealing effect as the inflation hose optimally adapts itself to the shape of the borehole. Over the whole length of the inflation hose an even contact pressure is granted.

Approvals

Inflatable packer with deaeration

Description

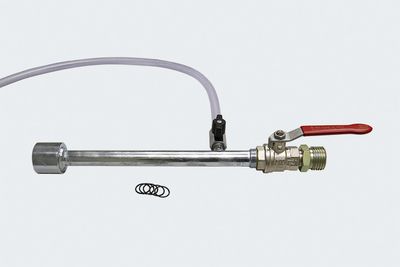

The venting of air guarantees that the entire cavity can be filled since no air is left to prevent the injection material from flowing. The inflatable packer with deaeration is especially useful in problematic structures where it is necessary to eliminate and prevent the formation of cavities which could allow water to penetrate.Application

The inflatable packer with deaeration is inserted into the borehole and expanded with minimum pressure to avoid damaging the structure. The filler material (acrylate gel) is injected with a suitable injection pump - the inflatable packer with deaeration allows air to be released so that the entire cavity can be filled.Cleaning

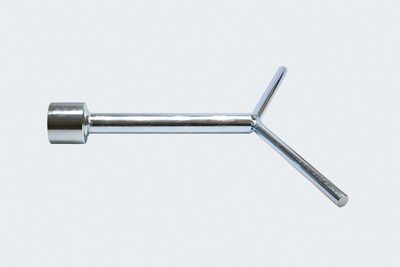

The cleaning set, developed especially for use with the inflatable packer, allows all relevant parts (including material tubes and purging conduits) to be thoroughly cleaned and re-used.Note

The single inflatable packer with air purge is available separately. All additional parts such as filling tube and venting tube are replaceable!

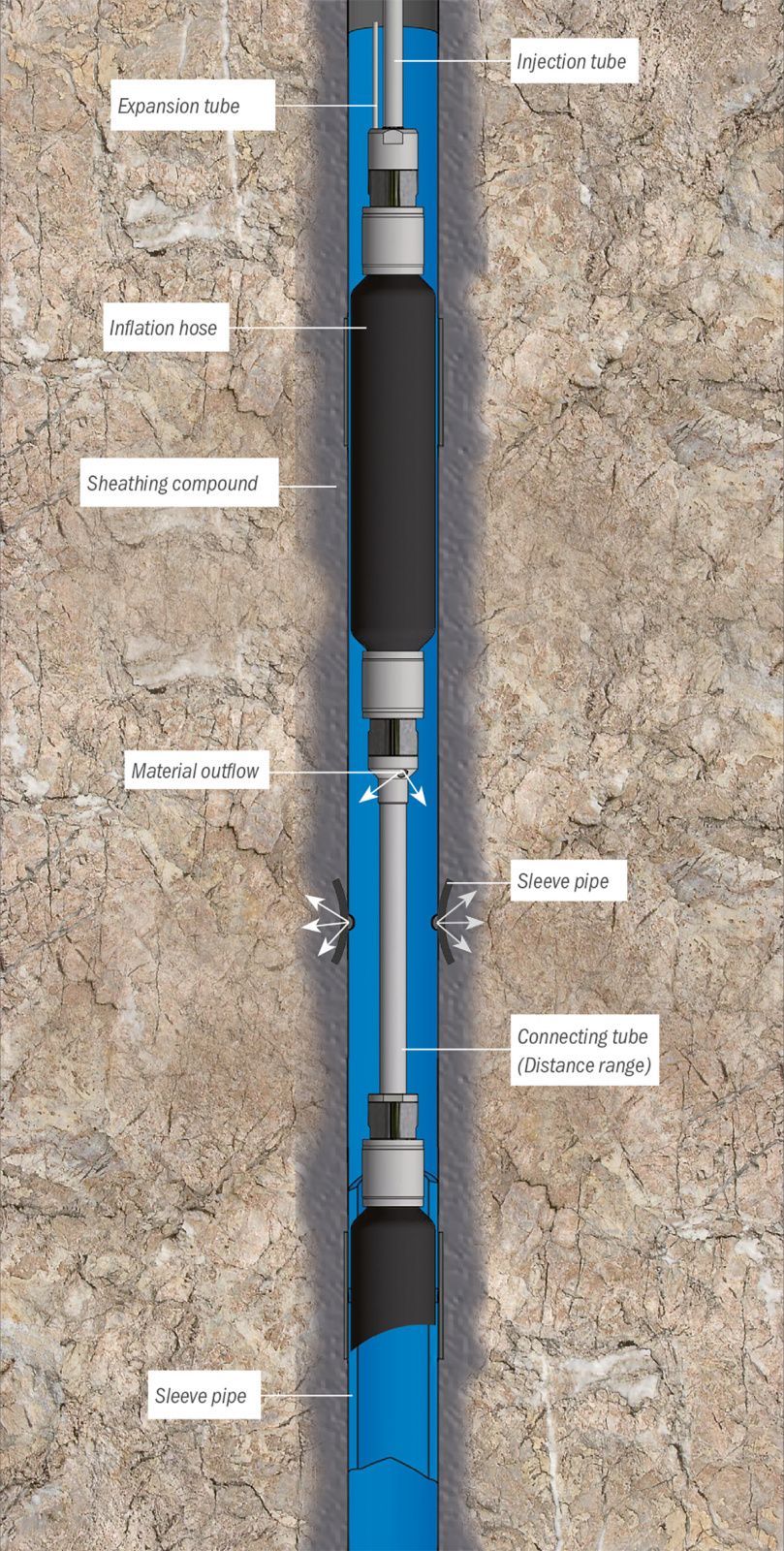

double inflatable packers Flex

Application range

The double inflatable packers are mainly used for injections with sleeve pipes. These injections serve for improvement of mechanical properties, for sealing purposes or for the consolidation of ground, rock, building components etc.Examples of application

- Consolidation of unconsolidated material

- Consolidation of fissured solid rock

- Injections in building components

- Injektionen in Bauteile

- Injections into the soil below building components

- Sealing works

- Lifting injection

Advantages of double inflatable packers

- Reusable

- Safe sealing

- Large inflation range: 1 double inflatable packer - different diameters

- Variable contact pressure

- Hardened sealing surface

- All parts are easily exchangeable

- In different lengths available

Sealing

The inflation hose of the double inflatable packers adapts itself to the shape of the boreholes or the sleeve pipe granting a good sealing which can be controlled by the inflation pressure. After the double inflatable packers have been inflated it is granted that the injection material can only come out laterally. This allows the accurate placing of the injection material.Expansion range inflation hose

The advantage of the double inflatable packers is the large expansion range of the inflation hose. The expansion amounts up to the double of the minimum borehole diameter so that only 1 packer is needed for sleeve pipes of varying sizes. Moreover the double inflatable packer generates a perfect sealing effect as the inflation hose optimally adapts itself to the shape of the borehole or the sleeve pipe. Over the whole length of the inflation hose an even contact pressure is granted.2C inflatable packers

Fields of application

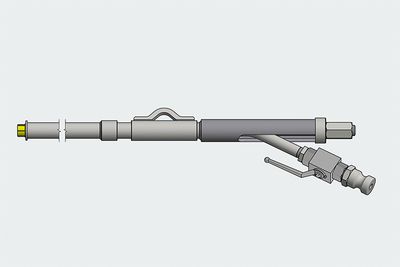

The 2C inflatable packers are used when quick-reacting two-component injection material is applied and the two components have to be delivered separately to the mixing tube.

Examples of application

- Consolidation of ground in different depths

- Consolidation of unconsolidated material

- Consolidation of fissured solid rock

- Injections in building components

- Injections in foundations

- Injections into the soil below building components

- Sealing works

- Lifting injection

Advantages

- The 2 components of the injection material are separately delivered to the mixing tube where it is mixed by a variable number of static mixing elements

- Several times reusable as both material tubes as well as the check valves can be rinsed separately at the packer

- Large expansion range of the inflation hose granting a perfect sealing effect in the borehole as well as a variable contact pressure

- Can be used in different depths

Details

A securing cord fixed to the packer serves for placing the 2C inflatable packer. After the injection work has been finished the securing cord can be used to remove the packer from the borehole. The advantage of the 2C inflatable packer is that the two components of the injection material are separately delivered to the mixing tube. Here a variable number of static mixing elements produce the mixing result which is best for the respective injection material. The two material tubes and check valves can be rinsed separately at the packer. A further advantage is the large expansion range of the inflation hose. According to each type of packer the expansion ranges up to the double of the minimum borehole diameter. Moreover the 2C inflatable packer generates a perfect sealing effect as the inflation hose optimally adapts itself to the shape of the borehole. That is why an even contact pressure is granted over the whole length of the inflation hose.Safety information inflatable packer

Filling

The filling operation should always be performed with a suitable filling liquid which is water in the normal case. The inflatable packer has to be vented before filling. Liquids provide more safety, since liquids cannot be compressed in contrast to gases. It is prohibited to use environmentally hazardous liquids or oil. Prior to filling you have to make sure that the packer has been deaerated. In case of filling the packers in a vertical borehole, the hydrostatic pressure of the water column in the filling pipe must also be taken into consideration (a 10 m water column corresponds to 1 bar). It can also complicate the draining of the packer. The packer may never be filled in the open air, but only in the installed state.Draining

The packer should not be moved until it is completely drained. We recommend that you drain the packer by means of vacuum, with the help of the draining device of the pump. The draining process takes some minutes. Clean the packer with water after each use. Each packer is tested with water on the test bench. Its tightness is determined in this way. The packers should be stored away from sunlight, since their natural rubber is sensitive to UV radiation, in particular sunlight. Never use the packer at its limit of maximum expansion.Expansion pressure

The filling pressure has to be selected according to the specifications, such as borehole diameter and injection pressure. It is not permissible to exceed the maximum filling pressure, since otherwise the packer might get damaged or destroyed. If the specifications are duly considered and adhered to, the packer will be securely fastened in the bore hole and will achieve a good sealing effect. In this way, the packer can be prevented from being pressed out. Pay attention to the hydrostatic pressure caused by influencing media.