Clamping and double packer

More InformationsFilter

9 Show Variants

3 Show Variants

2 Show Variants

2 Show Variants

4 Show Variants

2 Show Variants

2 Show Variants

4 Show Variants

7 Show Variants

10 Show Variants

4 Show Variants

4 Show Variants

5 Show Variants

3 Show Variants

9 Show Variants

5 Show Variants

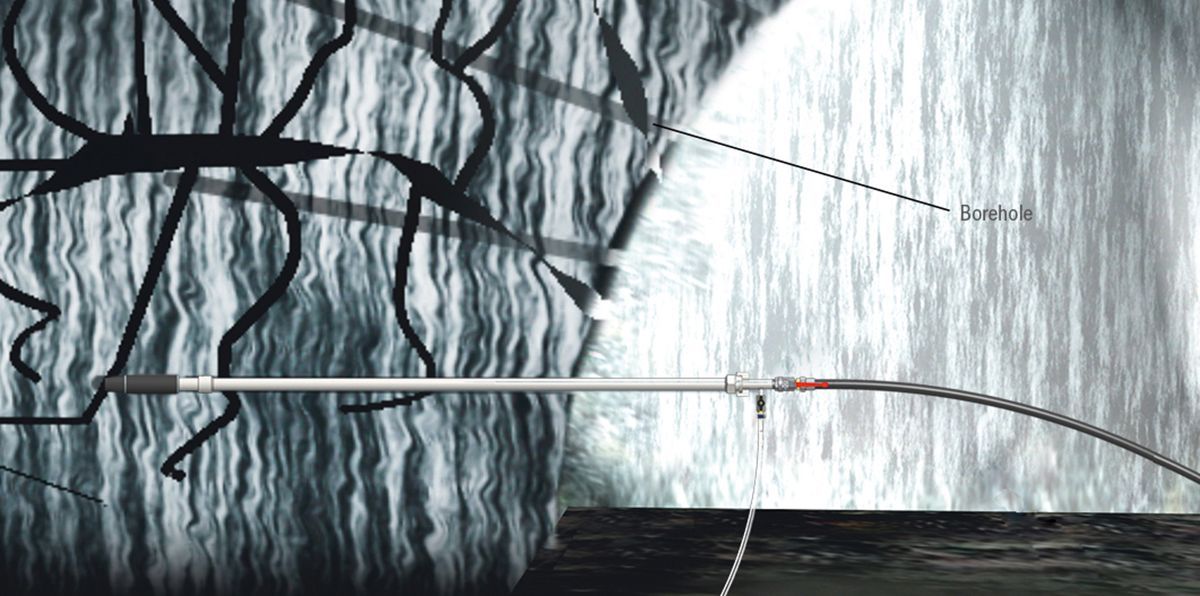

Tunnel and mountain injection with CLAMPING & double packers

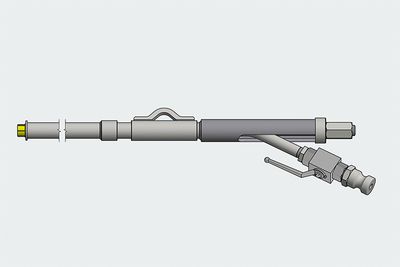

Clamping and double packers are used especially in mining and tunnelling. Clamping packers are mainly used for blasting. They enable a quick stabilisation and sealing of rock and rock with cementitious or chemical injection materials. The double packer, on the other hand, is a mechanical packer with two tensioning points. Like the inner and outer shells of a tunnel, for example, two components can be clamped together and leaks between the shells sealed. In addition, rock bolts can also be installed and injected directly during installation.

Tunnel and mountain injection

with clamping and double packers

open PDF

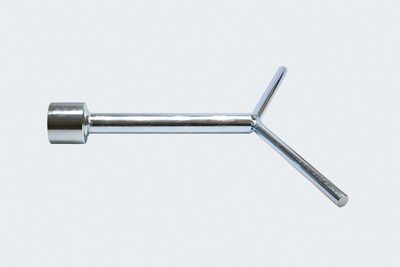

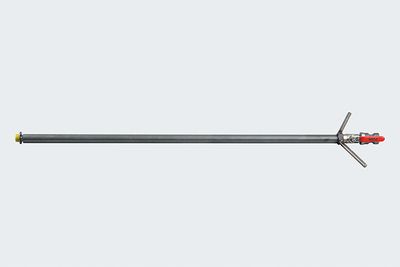

Clamping packer < 100 bar

The clamping packer is suitable to be used for sealing operations, for example in tunnelling. It allows a safe and fast injection of all injection materials on mineral basis as well as injection resins. An improved clamping system prevents damage to the securing rings.

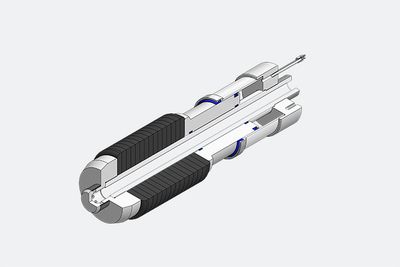

Clamping packer B < 100 bar

The clamping packer B is suitable to be used for sealing operations, for example in tunnelling. It allows a safe and fast injection of all injection materials on mineral basis as well as injection resins. The clamping packer B is clamped by using the extension and bayonet connection.

Advantage/Information

- Easy and simple handling

- Free passage Ø 20 mm

- Simple sealing by o-ring

- The bayonet coupling enables quick connection and disconnection

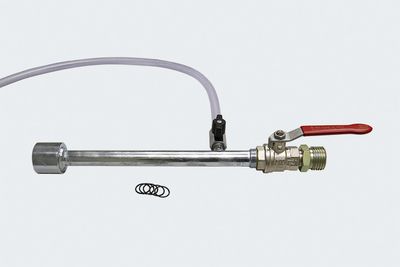

double packer

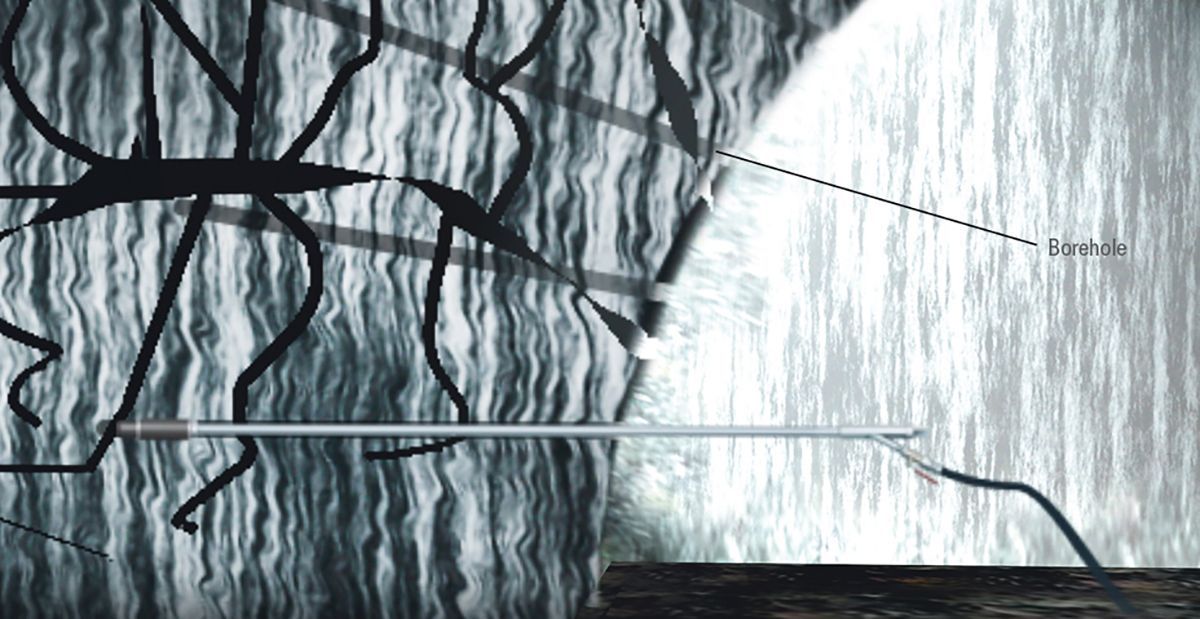

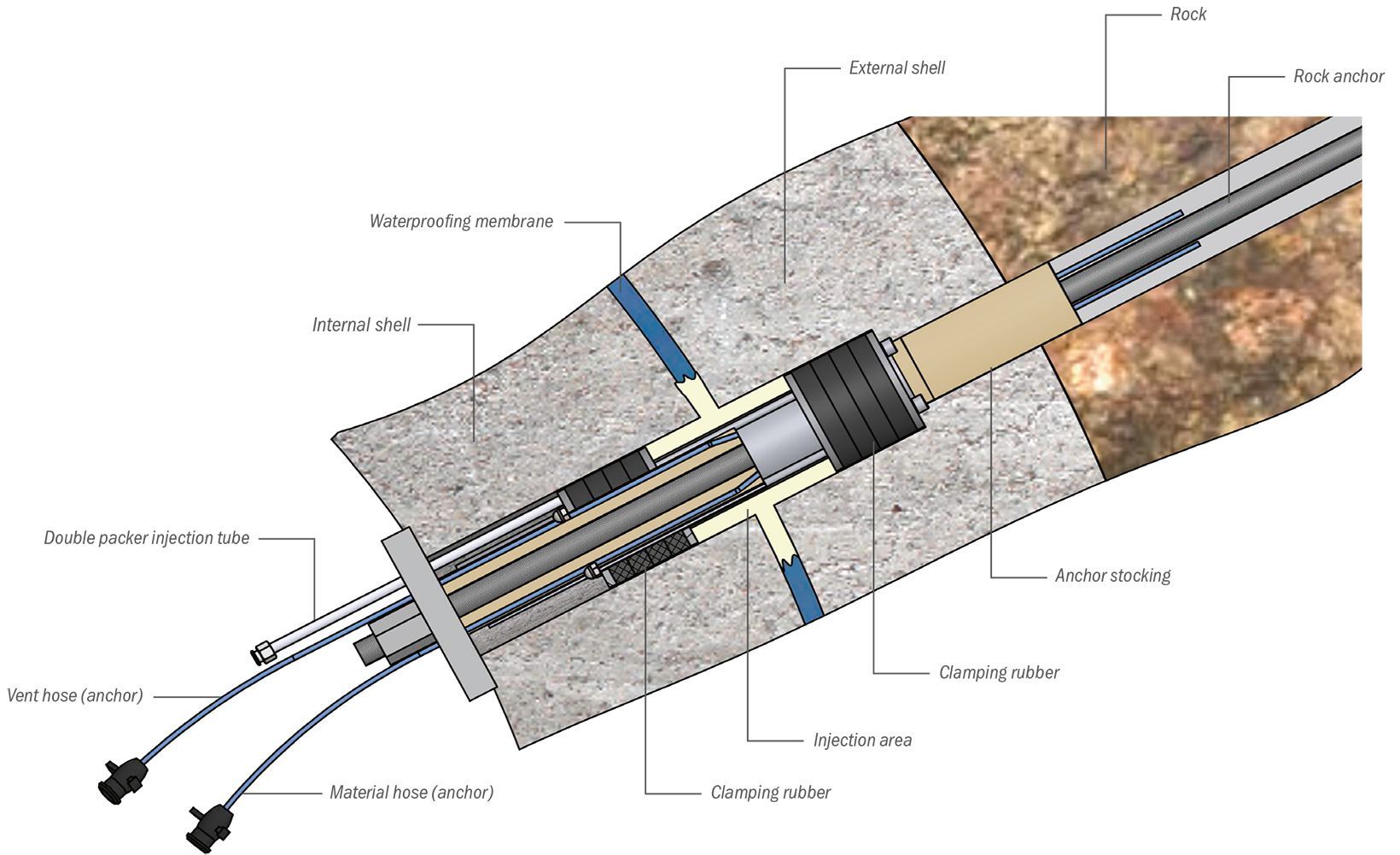

For placing the rock anchors, the required bores are drilled into the rock. Each anchor is provided with spacers, packed into the DESOI Anchor Stocking together with a material hose and a vent hose, and inserted into the respective bore hole. Now the double packer is positioned over the anchor so that the lateral injection area of the double packer is located square to the plastic waterproofing membrane.

The double packer is firmly clamped in the bore hole using the 4 axial clamping screws. To restore the watertightness, the waterproofing material is now injected through the injection tube of the double packer into the voids caused by drilling through the waterproofing membrane. The DESOI Anchor Mortar can be filled into the bore hole via the material hose in the anchor stocking.

The double packer is firmly clamped in the bore hole using the 4 axial clamping screws. To restore the watertightness, the waterproofing material is now injected through the injection tube of the double packer into the voids caused by drilling through the waterproofing membrane. The DESOI Anchor Mortar can be filled into the bore hole via the material hose in the anchor stocking.